PTSC attends the Science and Technology Exhibition on Petrovietnam's 50th anniversary of establishment

Latest

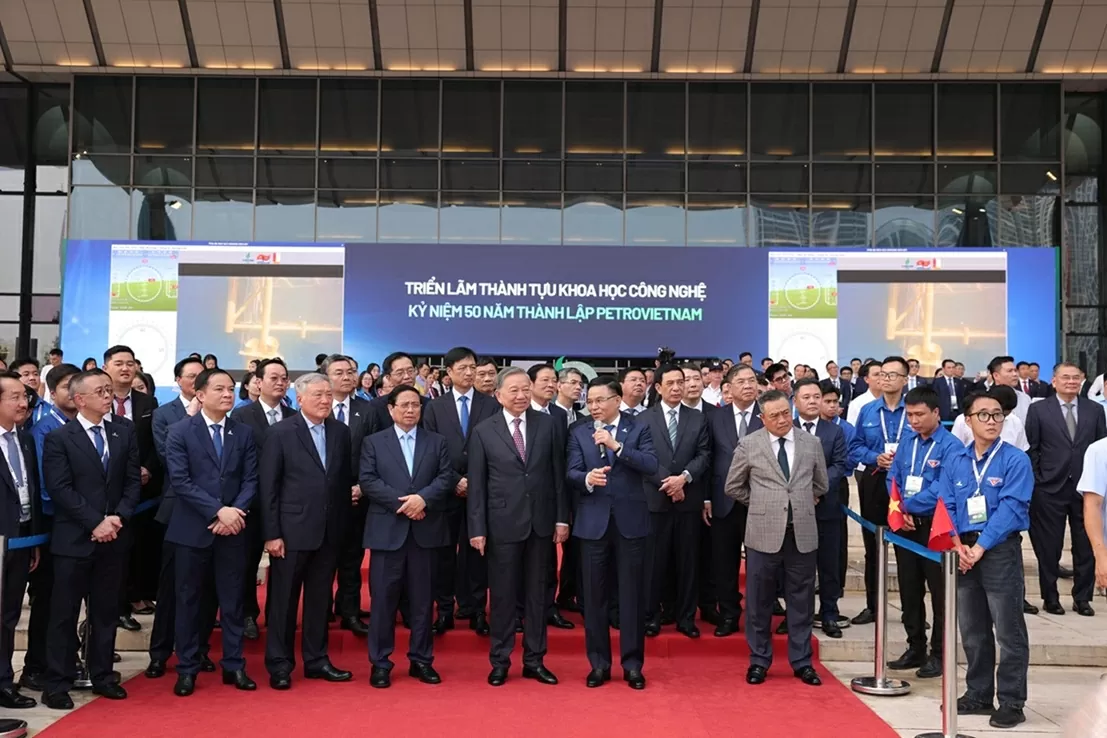

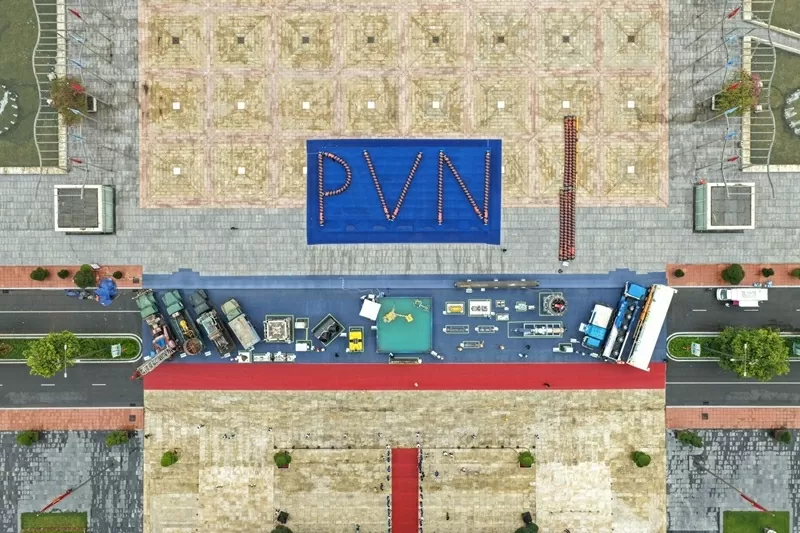

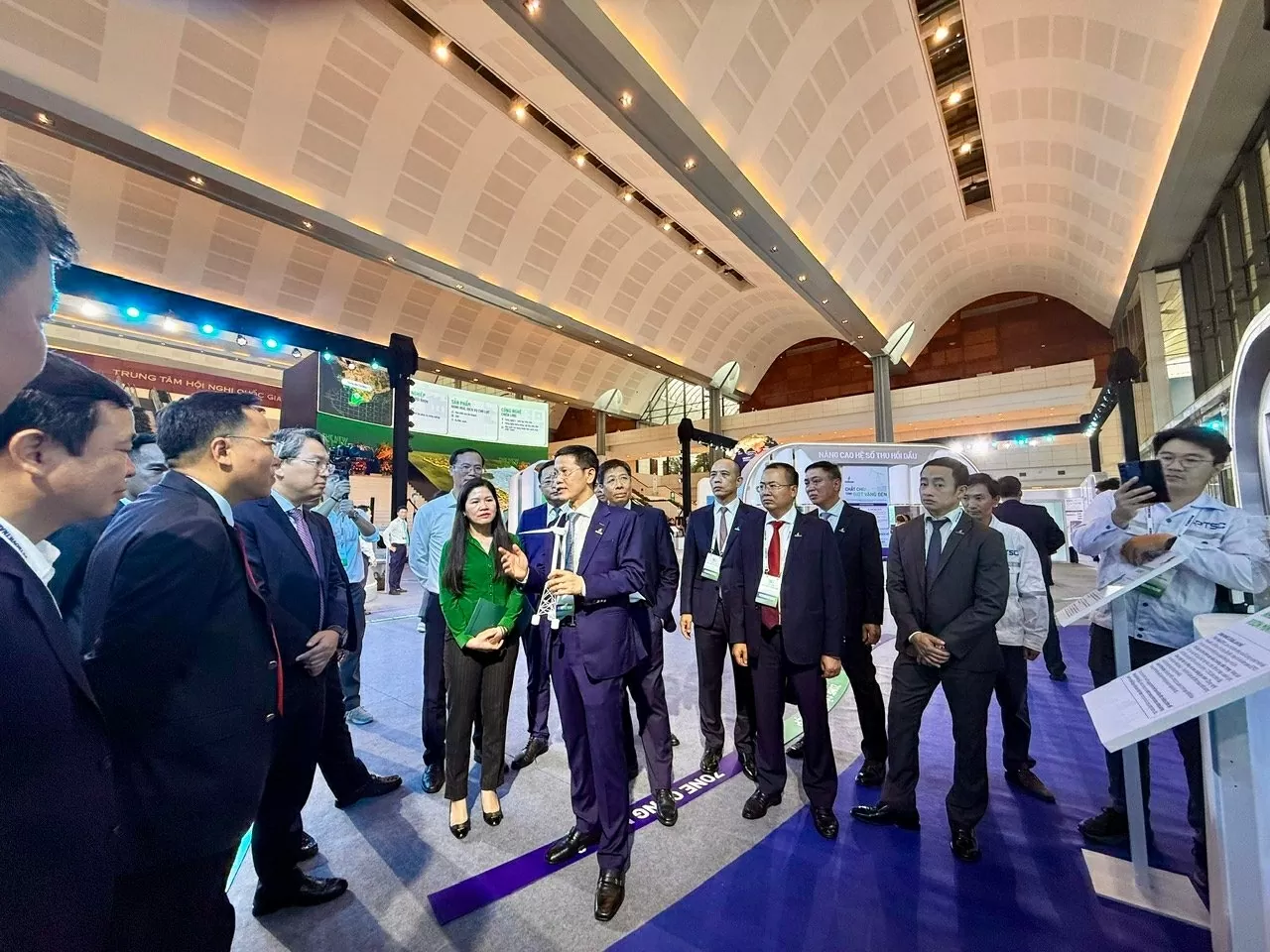

On this significant occasion, on September 21, 2025, Petrovietnam organised a Science and Technology Exhibition to showcase the outstanding achievements and applications of advanced science and technology in the oil and gas energy sector. Within the framework of the event, Vietnam Petroleum Technical Services Corporation (PTSC) participated in displaying 08 typical models/products in both indoor and outdoor areas. These are works that clearly reflect the capacity, strengths and pioneering role of PTSC in the fields of oil and gas, industry and offshore renewable energy.

|

| General Secretary To Lam, Prime Minister Pham Minh Chinh, and delegates visit the Petrovietnam exhibition. |

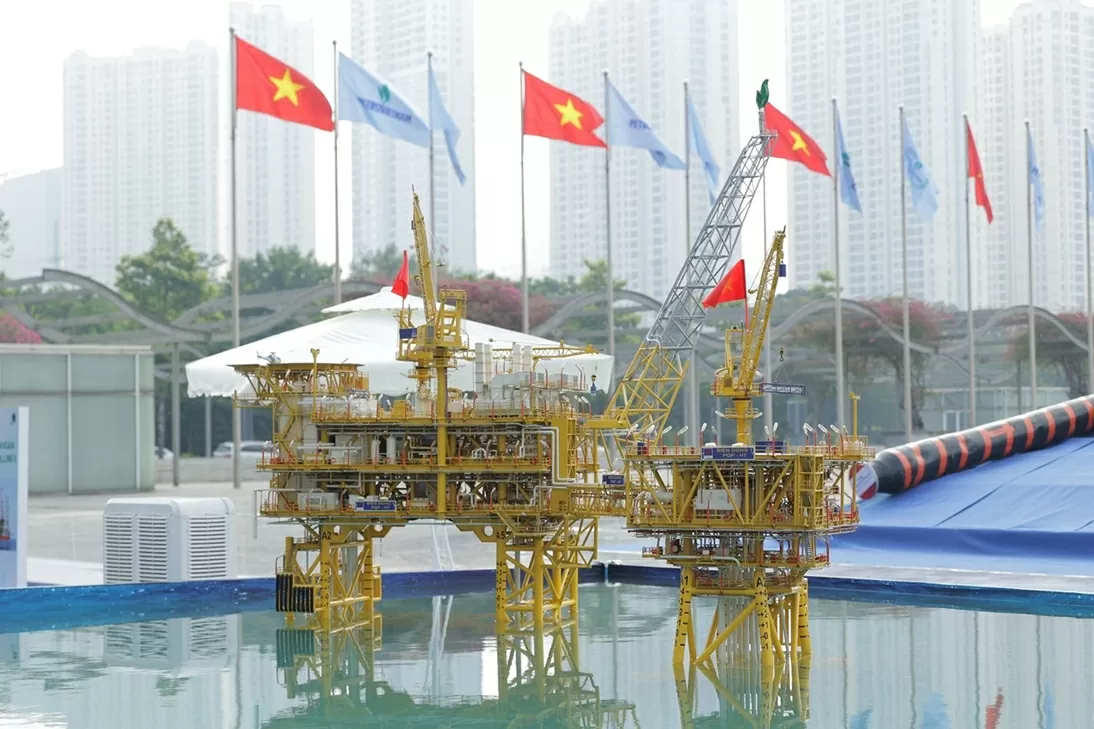

1. East Sea Project 01.

Bien Dong 1 is a national key oil and gas project, the largest in Vietnam by 2020, with a total construction volume exceeding 50,000 tons, including one central processing platform, two wellhead platforms, and a complex in-field pipeline system. The project was implemented over four years, covering all stages from design and procurement to construction, installation supervision, and testing, undertaken by a team of Vietnamese engineers. The resounding success of Bien Dong 1 not only affirms PTSC's capacity as a leading oil and gas engineering contractor in the region, trusted by international investors, but also marks a remarkable step forward in the maturity of the Vietnamese oil and gas industry, contributing to raising the country's position on the world energy map.

|

| The East Sea 1 model impresses at the Exhibition. |

2. Oil export pipes - A safe and effective solution in oil and gas exploitation.

Oil export pipes are specialised equipment in the oil and gas exploitation chain, used to transfer crude oil and condensate from FSO/FPSO tankers to receiving ships. PTSC currently owns and exploits 6 FSO/FPSOs. With the oil export pipes of the FPSO PTSC Lam Son project, this system has operated safely and effectively for 10 years, serving more than 70 oil export trips, with an output of approximately 17.5 million barrels, generating over $ 1 billion in revenue. The product is made of a 4-layer special rubber, meeting OCIMF GMPHOM 2009 standards, which enables it to float at sea, resist corrosion and UV, and withstand high pressure. Each pipe is 10.7 meters long, weighing between 1.1 and 1.4 tons, with a diameter of 51-60 centimetres.

|

| Oil export pipes - A safe and effective solution in oil and gas exploitation. |

3. Offshore Substation (OSS) – TPC II Project (Taiwan).

Considered the “heart” of an offshore wind farm, the transformer station is responsible for receiving all the electricity from the turbines and transmitting it to shore via a submarine cable system. At the TPC II project (Taiwan), PTSC has successfully manufactured and delivered an offshore transformer station – one of the most complex wind power projects in the region. The 3,390-ton topside is synchronously integrated with electrical systems, transformers, controls, and operating utilities, meeting DNV-GL’s strict inspection process and utilising a modern SCADA system that complies with international standards. The entire process, from design and fabrication to installation, testing, and handover, is managed by PTSC engineers. This success not only affirms Vietnam’s capacity to manufacture super-sized and super-heavy components but also elevates PTSC’s position in the global wind power supply chain.

4. Transition Piece (TP) – Key component in CHW2204 project (Taiwan).

As a connecting structure between the Jacket and the turbine tower, TP has the role of transmitting and distributing the load from the turbine to the foundation for 33 offshore wind power legs of the CHW2204 project. The product is manufactured from steel structures up to 87 mm thick, with large diameters, requiring extremely high manufacturing precision. The entire welding process is executed with advanced technology, utilising 100% NDT, and is combined with multi-layer anti-corrosion paint, ensuring durable operation in harsh offshore environments.

|

| PTSC General Director Tran Ho Bac introduces the process of producing electricity from offshore wind power. |

6. Design capacity for energy projects.

Design capacity is the core foundation that helps PTSC gradually transform from a pure construction and installation contractor to an EPCI general contractor for national and international energy projects. With a team of over 300 experienced engineers, PTSC has mastered all detailed technical aspects, performing comprehensive design packages for oil and gas, as well as offshore wind power projects, to ensure consistency, strict quality control, and optimised progress and costs. This is not only a clear demonstration of technological autonomy, but also affirms PTSC's position in implementing key energy projects at home and abroad. At the exhibition, PTSC engineers directly explained and demonstrated design capacity through visual models and advanced technical solutions, leaving a strong impression on leaders at all levels, partners, customers and visitors.

7. HVDC/HVAC underground cable model - PTSC Phu My High Voltage Cable Factory.

The submarine cable system is a key product in connecting and transmitting offshore wind power, manufactured at PTSC Phu My High Voltage Cable Factory - a symbol of modern power transmission technology in Vietnam and the ASEAN region. The factory is expected to have a scale of 20 hectares, operating two HVDC 525kV lines and one HVAC 66kV line, with a designed capacity of 500 km of HVDC cable/year and 200 km of HVAC cable/year. The product utilises advanced insulating material technology, enabling it to withstand harsh conditions underwater, ensuring safety, durability, and high reliability. Not only does the factory serve domestic projects, but it also aims to establish cross-border energy connections between Vietnam and Singapore, as well as between Vietnam and Malaysia, contributing to the formation of an "electric highway" in the region.

|

| PTSC engineers conduct design operations directly at the exhibition. |

8. Energy Highway.

In the coming time, PTSC will focus on researching and developing the North-South "Energy Highway" project under the sea, applying modern high-voltage direct current transmission technology. This is considered a strategic solution, contributing to ensuring national energy security, strengthening inter-regional connectivity, and opening up opportunities for Vietnam to become an energy centre of ASEAN, gradually forming a stable, flexible, and reliable domestic power grid when connecting to the ASEAN power grid in the future.

| Dai Hung - Phase 3 project produces first commercial oil flow: Petrovietnam The Phase 3 of the Dai Hung field development project (Dai Hung - Phase 3) has officially begun production of its first oil flow with ... |

| Petrovietnam ranks 11th in Fortune Southeast Asia 500, among Top 5 in Southeast Asia The Vietnam National Industry - Energy Group (Petrovietnam) has been ranked 11th in the 2025 Fortune Southeast Asia 500, according to the rankings released on ... |

| Petrovietnam Ca Mau Fertiliser JSC focuses on fertiliser for export Fertiliser exports continue to serve as a key growth driver for the Petrovietnam Ca Mau Fertiliser JSC (PVCFC) in the first half of 2025, with ... |

| Party General Secretary requested Petrovietnam to continue leading nation’s industrialisation, modernisation Party chief To Lam expressed his confidence that with its proud tradition, resilience, intellect, professionalism, and sense of solidarity, along with its faith and aspiration ... |

| PM Pham Minh Chinh: Oil and gas is considered a cornerstone of Vietnam-Russia Comprehensive Strategic Partnership WVR/VNA - Vietnam always considers oil and gas cooperation with Russia a cornerstone of their Comprehensive Strategic Partnership, with the decades-long tie-up between Petrovietnam and ... |